close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

FREQUENT ASKED QUESTIONS:

1 What is auto flip function? And what it can be used for?

For cabinet making or speaker making,we need have drilling ,routing or sloting on both sides of panel.For normal standard cnc, operator will run one file to finish on one side of panel, then manually flip panel, and then run another file for back side of panel. But now we design this special cnc with automatic flip device, so machine can first drilling slotting or routing on one side then machine automatically flip the panel and aligned it, then machine will start drilling slotting and routing on back side,and finally cutting. This machine can be used for all panels which need both sides machining,such as cabinet making ,wardrobe making ,speaker producing....

2 After both sides machining, how can we ensure the accuracy of both sides?

Equipped with aluminum bar for alignment of panel(all those aluminum bar will be milled by this cnc in order to keep X Y axis vertical accuracy),when we first machine front side of panel, we will cut two sides of panel along x and y axis, so after auto flip, then machine can align this panel with high accuracy.

3 Is there any other optional for this nesting cnc?

You can choose automatically loading and unloading table for this machine,and also you can choose one drilling head for this machine.

4 We need a Declaration of Conformity,a CE certificate, does this machine have it?

Yes,there is CE certificate and Declaration of Conformity for this machine.

QUALITY CONTROL:

On the basis of adhering to the ISO9001 certification system, our company exercises strict control over the production process, which is evident in the following key aspects:

1. Rail and Rack Installation Process:

Accuracy Control: During the installation of the guide rails and racks, our company maintains installation accuracy within 0.03mm. This stringent precision requirement ensures the smooth operation of the machine tool and minimizes mechanical wear.

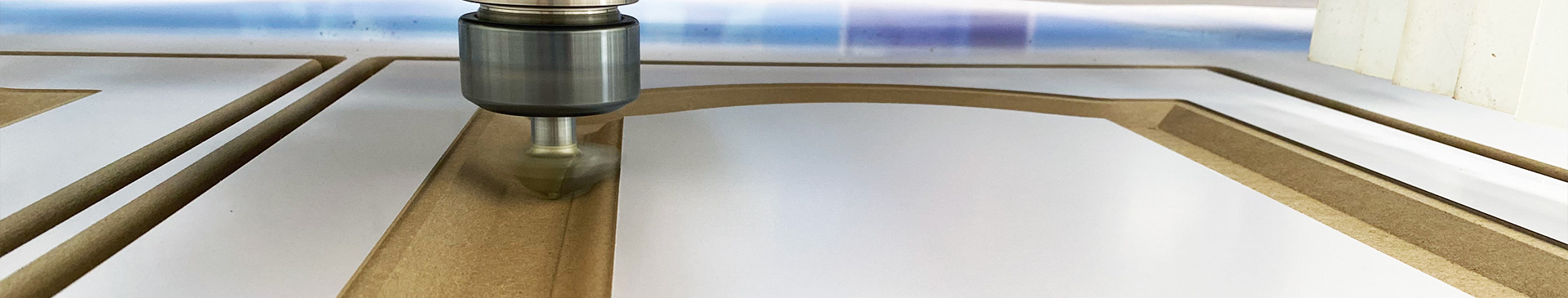

2. Spindle Verticality:

Verticality Requirements: The spindle's verticality is controlled within 0.03mm, which is crucial for ensuring precision and surface finish during machining. Typically, we perform spindle verticality checks twice: once before milling the vacuum table using a dial indicator to ensure accuracy, and again after milling to confirm that the accuracy remains within the 0.03mm threshold.

3. Accuracy Test After Complete Machine Installation:

Complete Machine Test: All scheduled machine tests are carried out, encompassing electrical performance, mechanical operation, and safety performance tests, to guarantee that the machine tool's overall performance aligns with design specifications.

Ball Bar Accuracy Test: Utilize a ball bar instrument for an accuracy test on the entire machine, which is a high-precision three-dimensional coordinate measuring system capable of detecting geometric and motion accuracy errors.

Data Analysis: A thorough analysis of the data is performed to identify any deviations in the machine tool's accuracy, followed by the implementation of appropriate corrective actions.

Through stringent control over these stages, our company can ensure the high precision and reliability of our cnc machines, meeting the rigorous quality standards required by the high-end manufacturing industry. Furthermore, these practices contribute to enhancing the market competitiveness and customer satisfaction of our products, aligning with the ISO9001 certification system's commitment to continuous improvement.

EXIHIBITION:

Our company actively participates in various domestic trade shows and exhibitions annually, especially CIFF Guangzhou and CIFF shanghai. These events are vital platforms for us to showcase our latest woodworking products, connect with domestic customers, and stay abreast of market trends and technological advancements within China in woodworking trends.

In addition to our domestic engagements, we also extend our reach by participating in international trade fairs. This global approach allows us to expand our market presence and engage with a broader customer base. We have attended exhibitions in countries like Russia and Vietnam.... which are strategic markets for our business.

Factory Sites:

| Series | NA-49FU | NA-410FU |

| Working size | 1220*2800*150mm | 1220*3050*150mm |

| Table size | 1220*2800mm | 1220*3050mm |

| Transmission | X Y rack and pinion,Z ball screw | X Y rack and pinion,Z ball screw |

| Spindle | 9kw ISO30 | 9kw ISO30 |

| Travelling speed | 50m/min | 50m/min |

| Working speed | 20m/min | 20m/min |

| Driving system | Inovance | Inovance |

| Controller | Syntec | Syntec |

| Voltage | AC380V/220V,50/60HZ,3PH | AC380V/220V,50/60HZ,3PH |

| Dimension | 10000*2260*2650mm | 11000*2260*2650mm |

FREQUENT ASKED QUESTIONS:

1 What is auto flip function? And what it can be used for?

For cabinet making or speaker making,we need have drilling ,routing or sloting on both sides of panel.For normal standard cnc, operator will run one file to finish on one side of panel, then manually flip panel, and then run another file for back side of panel. But now we design this special cnc with automatic flip device, so machine can first drilling slotting or routing on one side then machine automatically flip the panel and aligned it, then machine will start drilling slotting and routing on back side,and finally cutting. This machine can be used for all panels which need both sides machining,such as cabinet making ,wardrobe making ,speaker producing....

2 After both sides machining, how can we ensure the accuracy of both sides?

Equipped with aluminum bar for alignment of panel(all those aluminum bar will be milled by this cnc in order to keep X Y axis vertical accuracy),when we first machine front side of panel, we will cut two sides of panel along x and y axis, so after auto flip, then machine can align this panel with high accuracy.

3 Is there any other optional for this nesting cnc?

You can choose automatically loading and unloading table for this machine,and also you can choose one drilling head for this machine.

4 We need a Declaration of Conformity,a CE certificate, does this machine have it?

Yes,there is CE certificate and Declaration of Conformity for this machine.

QUALITY CONTROL:

On the basis of adhering to the ISO9001 certification system, our company exercises strict control over the production process, which is evident in the following key aspects:

1. Rail and Rack Installation Process:

Accuracy Control: During the installation of the guide rails and racks, our company maintains installation accuracy within 0.03mm. This stringent precision requirement ensures the smooth operation of the machine tool and minimizes mechanical wear.

2. Spindle Verticality:

Verticality Requirements: The spindle's verticality is controlled within 0.03mm, which is crucial for ensuring precision and surface finish during machining. Typically, we perform spindle verticality checks twice: once before milling the vacuum table using a dial indicator to ensure accuracy, and again after milling to confirm that the accuracy remains within the 0.03mm threshold.

3. Accuracy Test After Complete Machine Installation:

Complete Machine Test: All scheduled machine tests are carried out, encompassing electrical performance, mechanical operation, and safety performance tests, to guarantee that the machine tool's overall performance aligns with design specifications.

Ball Bar Accuracy Test: Utilize a ball bar instrument for an accuracy test on the entire machine, which is a high-precision three-dimensional coordinate measuring system capable of detecting geometric and motion accuracy errors.

Data Analysis: A thorough analysis of the data is performed to identify any deviations in the machine tool's accuracy, followed by the implementation of appropriate corrective actions.

Through stringent control over these stages, our company can ensure the high precision and reliability of our cnc machines, meeting the rigorous quality standards required by the high-end manufacturing industry. Furthermore, these practices contribute to enhancing the market competitiveness and customer satisfaction of our products, aligning with the ISO9001 certification system's commitment to continuous improvement.

EXIHIBITION:

Our company actively participates in various domestic trade shows and exhibitions annually, especially CIFF Guangzhou and CIFF shanghai. These events are vital platforms for us to showcase our latest woodworking products, connect with domestic customers, and stay abreast of market trends and technological advancements within China in woodworking trends.

In addition to our domestic engagements, we also extend our reach by participating in international trade fairs. This global approach allows us to expand our market presence and engage with a broader customer base. We have attended exhibitions in countries like Russia and Vietnam.... which are strategic markets for our business.

Factory Sites:

| Series | NA-49FU | NA-410FU |

| Working size | 1220*2800*150mm | 1220*3050*150mm |

| Table size | 1220*2800mm | 1220*3050mm |

| Transmission | X Y rack and pinion,Z ball screw | X Y rack and pinion,Z ball screw |

| Spindle | 9kw ISO30 | 9kw ISO30 |

| Travelling speed | 50m/min | 50m/min |

| Working speed | 20m/min | 20m/min |

| Driving system | Inovance | Inovance |

| Controller | Syntec | Syntec |

| Voltage | AC380V/220V,50/60HZ,3PH | AC380V/220V,50/60HZ,3PH |

| Dimension | 10000*2260*2650mm | 11000*2260*2650mm |

Copyright 2022 DWD MECHATRONICS CO.,LTD

Sitemap |Technology by leadong.com