close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

NA-2821FB

DWD

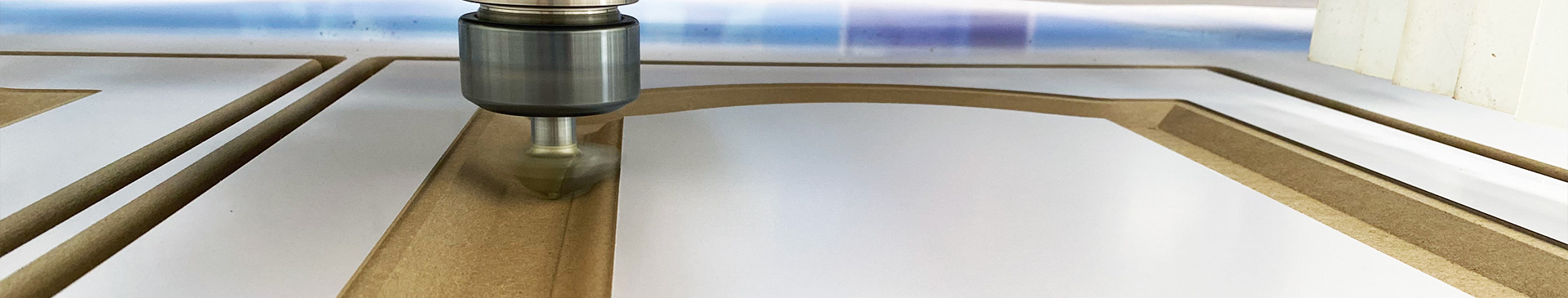

NA-2821FB CABINET MAKING NESTING CNC ROUTER MACHINE WITH DRILLING HEAD

DESCRIPTION:

The NA-2821FB model is a popular choice among large-scale furniture retailers due to its advanced features that enhance productivity. Its automatic loading and unloading capabilities significantly boost manufacturing efficiency. The machine is equipped with a 12-position linear tool magazine, which enables it to produce intricate items through a variety of operations such as routing, engraving, slotting, drilling, cutting, and more. This tool magazine is strategically placed under the gantry, reducing the time required for tool changes.

Standard with the model is a 12HP automatic tool change spindle that facilitates swift and seamless cutting. The higher cutting strength this feature provides also helps in minimizing tool wear and tear. Additionally, the machine is fitted with a drilling head that includes nine drill bits (five plus four), enabling the simultaneous drilling of multiple holes, which is a valuable asset in the furniture industry.

For a cleaner and more efficient work environment, the NA-2821FB comes with a new dust-free dust collector hood that effectively captures almost all dust generated during the cutting process. This is particularly beneficial for furniture shops where cleanliness is paramount. The machine also features a double-layer nesting vacuum table that securely holds panel materials in place. A large vacuum chamber exists between the two layers of the vacuum table, which, when the vacuum pump is activated, provides a strong absorption ability to keep materials firmly in place.

FEATURES

• 1 | Machine structure The entire machine framework is constructed using robust tubular steel. Once the stress-relieving process is completed, a five-axis CNC machining center is employed to meticulously machine the entire structure. This meticulous process establishes a solid foundation for the precise installation of linear rails and racks, ensuring higher accuracy in the machine's operation. |

|

• 2 | Gantry support The entire gantry support structure is crafted from cast iron, which, after undergoing precision machining, boasts a compression strength that is three to five times greater than that of steel. This material not only offers superior machinability and durability but also possesses outstanding anti-vibration characteristics. |

|

• 3 | Spindle The machine is equipped as standard with a 12HP air-cooled automatic tool change spindle featuring a standard ER32 collet and ISO30 tool holders. The spindle operates at speeds ranging from 3000 to 24000 revolutions per minute (RPM). |

|

• 4 | Dust free vacuum hood It is specially designed for panel furniture production.There are air blast in four different directions, so when tool cutting the panel, air will blow dust up, then dust collector can remove 90 percentage dust by pipes. |

|

• 5 | Material alignment stops We have mounted aluminum bars on the positioning cylinders of our machine. This feature maintains the panel's position, eliminating the need for operators to continually adjust the working origin; they only need to set it once. This is particularly crucial in the production of wardrobe cabinets, as it ensures that holes drilled on both sides of a panel remain accurately aligned. Additionally, during the unloading process, these aluminum bars lift and guide all completed panels to move forward in align manner. |

|

• 6 | 12- position linear tool magazine The linear tool magazine in this machine is strategically positioned beneath the gantry rather than at the rear of the machine. This placement significantly cuts down on tool changeover times and enhances operational efficiency. With a capacity for 12 tools, the machine is well-equipped to handle intricate processes seamlessly. |

|

• 7 | Drilling head 9V(5+4) The HQD 9V drill set is often used in conjunction with other machinery, such as CNC routers and drilling machines, to perform a variety of drilling tasks. It is suitable for high-density panel nesting and other heavy-duty applications where precision and durability are required . |

|

• 8 | Tool calibration The machine's automatic tool calibration feature autonomously determines the length of each tool, providing the controller with precise measurements. This accuracy enables the machine to execute complex multi-tool operations flawlessly. Adjacent to the calibration station, an air pipe is positioned to blow off any dust from the tool sensor's surface prior to calibration, ensuring that high precision is maintained. Notably, the tool sensor has a size of 100mm, which allows for the use of larger tools on this nesting CNC machine. |

|

• 9 | Tool holder clamp The machine is equipped with a specially designed loading and unloading device that accommodates panels of various sizes without any limitations regarding their dimensions, whether large or small. |

|

• 10 | Loading table (scissor lift table) The scissor lift table on this machine is engineered to elevate panels to a predetermined height, allowing for the simultaneous loading of new panels and unloading of completed ones. An integrated height sensor precisely regulates the elevation of the scissor lift table to ensure smooth and accurate panel handling. |

|

• 11 | Unloading table (conveyor belt table) Completed panels are guided onto the conveyor belt table. As the panels approach the front sensor, the belt halts its rotation. Once the operator has removed the panels at the front, the belt resumes rotation, pushing the remaining panels forward. Additionally, operators have the option to attach barcodes to the finished panels for tracking and identification purposes. |

|

FREQUENT ASKED QUESTIONS:

1 What are the maximum cutting dimensions for this CNC nesting machine, and is it possible to tailor the maximum cutting size to my specific requirements?

This CNC nesting router is capable of handling a maximum cutting size of 2100mm by 2800mm, which corresponds to the common European panel dimensions of 2070mm by 2800mm. Furthermore, if you require a larger cutting size, the machine can be customized to accommodate your specific needs.

2 Will the machine come with operating instructions, enabling me to learn how to use the CNC nesting machine?

The machine tool box includes a pen drive containing detailed instructions for operation and maintenance. In addition to that, we provide YouTube videos demonstrating the installation and operation of the CNC router machine. Moreover, you have the option to engage in a direct video chat with our engineer for further assistance.

3 What G-code does the machine support, and is it possible to integrate a post-processor with our existing software?

This machine features an auto-labeling function and requires not only the standard .nc file but also XML and BMP files for labels. You can request our sales engineers to send you the detailed format and explanation of these files to share with your software supplier. Rest assured, this machine is compatible with your software.

4 We require a Declaration of Conformity and a CE certificate for our records; does this machine come with these documents?

Yes, this machine is accompanied by a CE certificate and a Declaration of Conformity, ensuring compliance with European safety standards.

NA-2821FB CABINET MAKING NESTING CNC ROUTER MACHINE WITH DRILLING HEAD

DESCRIPTION:

The NA-2821FB model is a popular choice among large-scale furniture retailers due to its advanced features that enhance productivity. Its automatic loading and unloading capabilities significantly boost manufacturing efficiency. The machine is equipped with a 12-position linear tool magazine, which enables it to produce intricate items through a variety of operations such as routing, engraving, slotting, drilling, cutting, and more. This tool magazine is strategically placed under the gantry, reducing the time required for tool changes.

Standard with the model is a 12HP automatic tool change spindle that facilitates swift and seamless cutting. The higher cutting strength this feature provides also helps in minimizing tool wear and tear. Additionally, the machine is fitted with a drilling head that includes nine drill bits (five plus four), enabling the simultaneous drilling of multiple holes, which is a valuable asset in the furniture industry.

For a cleaner and more efficient work environment, the NA-2821FB comes with a new dust-free dust collector hood that effectively captures almost all dust generated during the cutting process. This is particularly beneficial for furniture shops where cleanliness is paramount. The machine also features a double-layer nesting vacuum table that securely holds panel materials in place. A large vacuum chamber exists between the two layers of the vacuum table, which, when the vacuum pump is activated, provides a strong absorption ability to keep materials firmly in place.

FEATURES

• 1 | Machine structure The entire machine framework is constructed using robust tubular steel. Once the stress-relieving process is completed, a five-axis CNC machining center is employed to meticulously machine the entire structure. This meticulous process establishes a solid foundation for the precise installation of linear rails and racks, ensuring higher accuracy in the machine's operation. |

|

• 2 | Gantry support The entire gantry support structure is crafted from cast iron, which, after undergoing precision machining, boasts a compression strength that is three to five times greater than that of steel. This material not only offers superior machinability and durability but also possesses outstanding anti-vibration characteristics. |

|

• 3 | Spindle The machine is equipped as standard with a 12HP air-cooled automatic tool change spindle featuring a standard ER32 collet and ISO30 tool holders. The spindle operates at speeds ranging from 3000 to 24000 revolutions per minute (RPM). |

|

• 4 | Dust free vacuum hood It is specially designed for panel furniture production.There are air blast in four different directions, so when tool cutting the panel, air will blow dust up, then dust collector can remove 90 percentage dust by pipes. |

|

• 5 | Material alignment stops We have mounted aluminum bars on the positioning cylinders of our machine. This feature maintains the panel's position, eliminating the need for operators to continually adjust the working origin; they only need to set it once. This is particularly crucial in the production of wardrobe cabinets, as it ensures that holes drilled on both sides of a panel remain accurately aligned. Additionally, during the unloading process, these aluminum bars lift and guide all completed panels to move forward in align manner. |

|

• 6 | 12- position linear tool magazine The linear tool magazine in this machine is strategically positioned beneath the gantry rather than at the rear of the machine. This placement significantly cuts down on tool changeover times and enhances operational efficiency. With a capacity for 12 tools, the machine is well-equipped to handle intricate processes seamlessly. |

|

• 7 | Drilling head 9V(5+4) The HQD 9V drill set is often used in conjunction with other machinery, such as CNC routers and drilling machines, to perform a variety of drilling tasks. It is suitable for high-density panel nesting and other heavy-duty applications where precision and durability are required . |

|

• 8 | Tool calibration The machine's automatic tool calibration feature autonomously determines the length of each tool, providing the controller with precise measurements. This accuracy enables the machine to execute complex multi-tool operations flawlessly. Adjacent to the calibration station, an air pipe is positioned to blow off any dust from the tool sensor's surface prior to calibration, ensuring that high precision is maintained. Notably, the tool sensor has a size of 100mm, which allows for the use of larger tools on this nesting CNC machine. |

|

• 9 | Tool holder clamp The machine is equipped with a specially designed loading and unloading device that accommodates panels of various sizes without any limitations regarding their dimensions, whether large or small. |

|

• 10 | Loading table (scissor lift table) The scissor lift table on this machine is engineered to elevate panels to a predetermined height, allowing for the simultaneous loading of new panels and unloading of completed ones. An integrated height sensor precisely regulates the elevation of the scissor lift table to ensure smooth and accurate panel handling. |

|

• 11 | Unloading table (conveyor belt table) Completed panels are guided onto the conveyor belt table. As the panels approach the front sensor, the belt halts its rotation. Once the operator has removed the panels at the front, the belt resumes rotation, pushing the remaining panels forward. Additionally, operators have the option to attach barcodes to the finished panels for tracking and identification purposes. |

|

FREQUENT ASKED QUESTIONS:

1 What are the maximum cutting dimensions for this CNC nesting machine, and is it possible to tailor the maximum cutting size to my specific requirements?

This CNC nesting router is capable of handling a maximum cutting size of 2100mm by 2800mm, which corresponds to the common European panel dimensions of 2070mm by 2800mm. Furthermore, if you require a larger cutting size, the machine can be customized to accommodate your specific needs.

2 Will the machine come with operating instructions, enabling me to learn how to use the CNC nesting machine?

The machine tool box includes a pen drive containing detailed instructions for operation and maintenance. In addition to that, we provide YouTube videos demonstrating the installation and operation of the CNC router machine. Moreover, you have the option to engage in a direct video chat with our engineer for further assistance.

3 What G-code does the machine support, and is it possible to integrate a post-processor with our existing software?

This machine features an auto-labeling function and requires not only the standard .nc file but also XML and BMP files for labels. You can request our sales engineers to send you the detailed format and explanation of these files to share with your software supplier. Rest assured, this machine is compatible with your software.

4 We require a Declaration of Conformity and a CE certificate for our records; does this machine come with these documents?

Yes, this machine is accompanied by a CE certificate and a Declaration of Conformity, ensuring compliance with European safety standards.

Copyright 2022 DWD MECHATRONICS CO.,LTD

Sitemap |Technology by leadong.com