close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

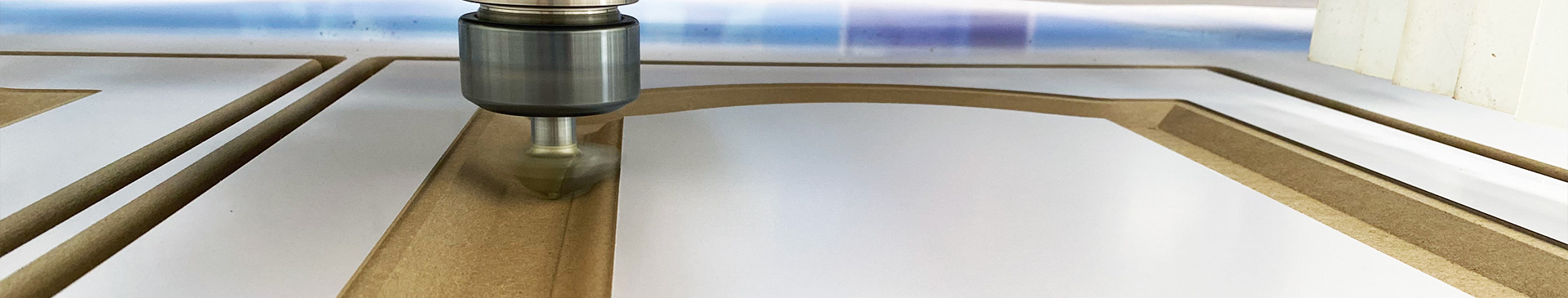

NM-1325 CNC ROUTER MACHINE

DESCRIPTION:

NM series cnc router machine is economic model specially designed for wood engraving.One 3.5kw spindle are equipped with machine for cutting,routing,slotting and milling.Compared with normal cnc router, this machine adopts double layer PVC nesting vacuum table,and also there are five positioning cylinder installed on the machine, which is convenient for positioning materials on the vacuum table

FEATURES

• 1 | Spindle It comes standard with one 3.5kw air cooling spindle ER25 |

|

• 2 | Material alignment stops These material alignment stops plays a very important role during panel alignment. It can keeps panel positions so there is no need for operator to change working origins always, they just need set it one time.And it is very important in wardrobe cabinet production.Because sometimes we need drill holes on one panel both sides, those alignment stops will keeps accuracy of those holes. |

|

• 3 | Tool calibration This movable tool sensor will ensure tool length accuracy,after we change tool, we just need put tool sensor on the top of material and then calibrate new tool again. |

|

• 4 | Vacuum zones 4 vacuum zones is standard ,which is convenient for different size material |

|

SAMPLES:

PARAMETER:

Working size 1300*2500*200mm

Rapid speed 25m/min

Spindle 3.5kw ER25

Driver motor Leadshine stepper

Controller Mach3 controller

Dimension 3350*1960*2150mm

NM-1325 CNC ROUTER MACHINE

DESCRIPTION:

NM series cnc router machine is economic model specially designed for wood engraving.One 3.5kw spindle are equipped with machine for cutting,routing,slotting and milling.Compared with normal cnc router, this machine adopts double layer PVC nesting vacuum table,and also there are five positioning cylinder installed on the machine, which is convenient for positioning materials on the vacuum table

FEATURES

• 1 | Spindle It comes standard with one 3.5kw air cooling spindle ER25 |

|

• 2 | Material alignment stops These material alignment stops plays a very important role during panel alignment. It can keeps panel positions so there is no need for operator to change working origins always, they just need set it one time.And it is very important in wardrobe cabinet production.Because sometimes we need drill holes on one panel both sides, those alignment stops will keeps accuracy of those holes. |

|

• 3 | Tool calibration This movable tool sensor will ensure tool length accuracy,after we change tool, we just need put tool sensor on the top of material and then calibrate new tool again. |

|

• 4 | Vacuum zones 4 vacuum zones is standard ,which is convenient for different size material |

|

SAMPLES:

PARAMETER:

Working size 1300*2500*200mm

Rapid speed 25m/min

Spindle 3.5kw ER25

Driver motor Leadshine stepper

Controller Mach3 controller

Dimension 3350*1960*2150mm

Copyright 2022 DWD MECHATRONICS CO.,LTD

Sitemap |Technology by leadong.com