close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

PRODUCT DESCRIPTION:

NA series cabinet making cnc machine is widely used in high volume furniture shops.It has some basic functions

as the following shows:

working size 1220*3000*150mm

12hp spindle with automatic tool change function(ISO30)

12-position linear tool magazine on the back of machine

handel controller which is easy to operate

FEATURES

• 1 | Machine structure All machine structure are welded by heavy duty tubular.After stress relieved,we use 5 axis cnc machining center to machine this total machine structure,which lays the foundation of higher accuracy of linear rail and rack installation. |

|

• 2 | Gantry support All gantry support is made from cast iron.After precision machining,it has three to five times more compression strength compared to steel.and it has good machinability ,durability and excellent anti-vibration properties. |

|

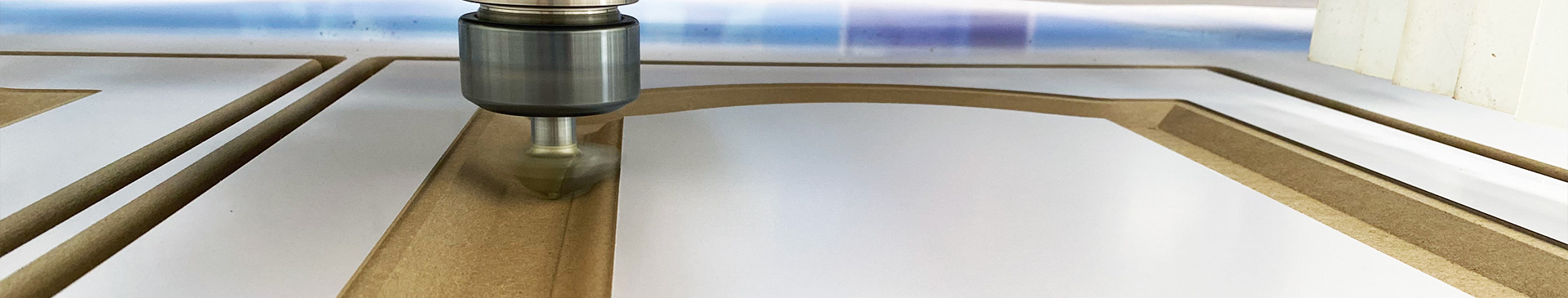

• 3 | Spindle It comes standard with 12HP air cooling automatic tool change spindle with standard ER32 collet and ISO30 tool holders.Its spindle speed is from 3000 to 24000RPM |

|

• 4 | Material alignment stops These material alignment stops plays a very important role during panel alignment. It can keeps panel positions so there is no need for operator to change working origins always, they just need set it one time.And it is very important in wardrobe cabinet production.Because sometimes we need drill holes on one panel both sides, those alignment stops will keeps accuracy of those holes. |

|

• 5 | 12- position linear tool magazine This linear tool magazine is installed back of machine,and we installed one protection cover under this linear tool magazine.If tool holder drop off, it will protect the tool. |

|

• 6 | Nesting vacuum table There is one big vacuum chamber between two layer of nesting vacuum table,this will improve absorption capability of vacuum table, thus panel material will be hold tightly.Besides we have installed big screws in vacuum table which are used to fix sacrificed MDF sheet,it is much more easier for operator compared to gluing. |

|

• 7 | Tool calibration Automatic tool calibration will measure all tools length automatically,thus controller will know very accurate length of each tool, then machine will finish multi tool process smoothly. Besides there is one air pipe beside the tool calibration, before tool calibration, the air pipe will open to remove dust on the surface of tool sensor, which will keeps high accuracy. |

|

• 8 | Tool holder clamp This holder clamp supply one easy way for operator to change tool manually only with one ER32 wrench.Compared normal way to tight collet nut with two wrenches,this way is not only safer,but also it can protect tools in the spindle. |

|

• 9 | Plastic drag chain We separate encoder cable ,motor cable,and air pipe when we install then into plastic drag chain by plastic isolator. Thus encoder signal will not affacted by motor cable with high voltage,at the same time, it will protect those cables and pipes. |

|

QUALITY CONTROL :

• 1 | X Y axis vertical accuracy After adjusting verticality of x y axis is less than 0.03mm,then we install location pins between gantry and gantry support. |

|

• 2 | Adjustable screws After adjusting verticality of x y axis is less than 0.03mm,we also install adjustable screws between gantry and gantry support.(there is one adjustable screw together on each gantry support) |

|

• 3 | Spindle vertical accuracy spindle verticality is also very important. First we adjust spindle verticality less than 0.03mm,then we install location pins on spindle plate |

|

Multi use cabinet making application

3D Carving

Acrylic Fabrication

Aluminum Fabrication

Architectural Millwork

Woodworking Applications

Aerospace

Cabinetry

Exhibits and Fixtures

Sign Making

PRODUCT DESCRIPTION:

NA series cabinet making cnc machine is widely used in high volume furniture shops.It has some basic functions

as the following shows:

working size 1220*3000*150mm

12hp spindle with automatic tool change function(ISO30)

12-position linear tool magazine on the back of machine

handel controller which is easy to operate

FEATURES

• 1 | Machine structure All machine structure are welded by heavy duty tubular.After stress relieved,we use 5 axis cnc machining center to machine this total machine structure,which lays the foundation of higher accuracy of linear rail and rack installation. |

|

• 2 | Gantry support All gantry support is made from cast iron.After precision machining,it has three to five times more compression strength compared to steel.and it has good machinability ,durability and excellent anti-vibration properties. |

|

• 3 | Spindle It comes standard with 12HP air cooling automatic tool change spindle with standard ER32 collet and ISO30 tool holders.Its spindle speed is from 3000 to 24000RPM |

|

• 4 | Material alignment stops These material alignment stops plays a very important role during panel alignment. It can keeps panel positions so there is no need for operator to change working origins always, they just need set it one time.And it is very important in wardrobe cabinet production.Because sometimes we need drill holes on one panel both sides, those alignment stops will keeps accuracy of those holes. |

|

• 5 | 12- position linear tool magazine This linear tool magazine is installed back of machine,and we installed one protection cover under this linear tool magazine.If tool holder drop off, it will protect the tool. |

|

• 6 | Nesting vacuum table There is one big vacuum chamber between two layer of nesting vacuum table,this will improve absorption capability of vacuum table, thus panel material will be hold tightly.Besides we have installed big screws in vacuum table which are used to fix sacrificed MDF sheet,it is much more easier for operator compared to gluing. |

|

• 7 | Tool calibration Automatic tool calibration will measure all tools length automatically,thus controller will know very accurate length of each tool, then machine will finish multi tool process smoothly. Besides there is one air pipe beside the tool calibration, before tool calibration, the air pipe will open to remove dust on the surface of tool sensor, which will keeps high accuracy. |

|

• 8 | Tool holder clamp This holder clamp supply one easy way for operator to change tool manually only with one ER32 wrench.Compared normal way to tight collet nut with two wrenches,this way is not only safer,but also it can protect tools in the spindle. |

|

• 9 | Plastic drag chain We separate encoder cable ,motor cable,and air pipe when we install then into plastic drag chain by plastic isolator. Thus encoder signal will not affacted by motor cable with high voltage,at the same time, it will protect those cables and pipes. |

|

QUALITY CONTROL :

• 1 | X Y axis vertical accuracy After adjusting verticality of x y axis is less than 0.03mm,then we install location pins between gantry and gantry support. |

|

• 2 | Adjustable screws After adjusting verticality of x y axis is less than 0.03mm,we also install adjustable screws between gantry and gantry support.(there is one adjustable screw together on each gantry support) |

|

• 3 | Spindle vertical accuracy spindle verticality is also very important. First we adjust spindle verticality less than 0.03mm,then we install location pins on spindle plate |

|

Multi use cabinet making application

3D Carving

Acrylic Fabrication

Aluminum Fabrication

Architectural Millwork

Woodworking Applications

Aerospace

Cabinetry

Exhibits and Fixtures

Sign Making

Copyright 2022 DWD MECHATRONICS CO.,LTD

Sitemap |Technology by leadong.com