close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

DESCRIPTION

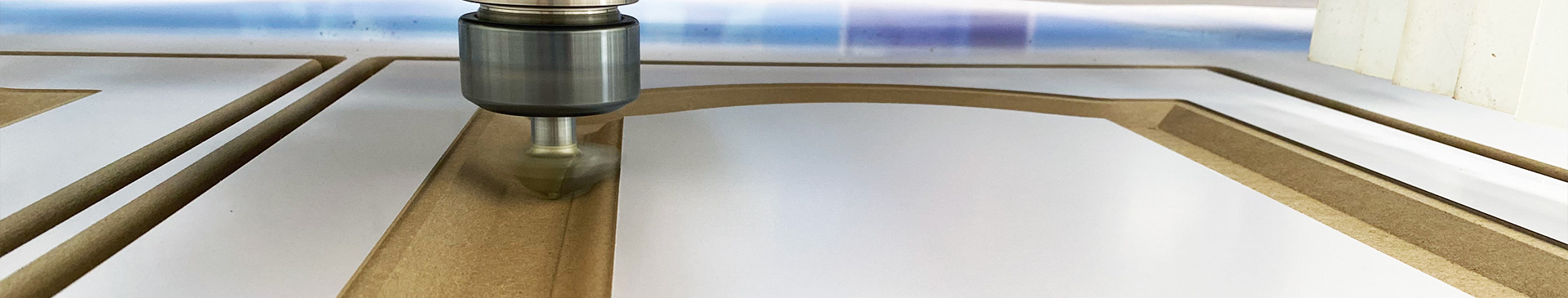

1. Intelligent production solutions: Automatic nested cell is one of the intelligent solutions in the automatic production line of panel furniture. By integrating the labeling system, nested CNC router and a variety of auxiliary equipment, it minimizes manpower demand, improves material utilization, and supports large-scale and customized production.

2. Efficient automation process: The unit is composed of high-speed automatic labeling machine, two automatic loading and unloading ATC nested CNC machines, power drum line and central control system. The operator simply places the board on the lifting platform, the labeling machine will automatically label it, and the central control system then automatically assigns it to the nested center for cutting.

3. Optional robot system: The optional robot system can be used to complete pallet, surplus materials and waste output.

4. Central control system: with the function of optimizing the cutting program, saving time and reducing plate waste. At the same time, it supports the field supply of plates, and single plates can be processed without making documents and importing data. Up to approximately 230-260 panels in 8 hours.

5. Easy operation: Even ordinary workers can easily operate the nested units. The operator only needs to copy the processing program to the central control system and start the machine without operating each machine.

6. Optimized plate treatment: Optimize and rapidly promote the wood board treatment under the same order to improve efficiency and bring significant benefits.

7. Continuous multiple shift operation: nested units can run continuously in several shifts, reducing human restrictions and standby time.

8. Reduce production errors and material damage: effectively reduce production errors and material damage caused by human operation.

9. Production process monitoring: more convenient to monitor the whole production process.

10. Customization options: Customers can customize the size of the machine and many other configurations, including the size of the unit, the number and model of nested machines.

FREQUENT ASKED QUESTIONS:

1 Can i just buy one part of machine ,and later when big production needed, i will buy other other part?

Definitely yes, you can tell us your production area ,so let us make layout for you.All input and output port prepared well if you just buy part of them, and later can just buy and connect two nesting cnc machine together.

2 What is maximum cutting size of this machine? Or Can i customize maximum cutting size of nesting cnc machine?

The maximum cutting size of this nesting cnc router is 1220*2800mm,option is suitable for European panel size 2070*2800mm. And you can also customize machine size if you have bigger size needed.

3 Will there be instructions attached with machine,which i can follow to learn how to operate this cnc nesting machine?

There is one pen driver attached in machine tool box, in which there is instructions operation and maintenance,besides we have YouTube videos to show installation and operation of cnc router machine,except all of this ,you can choose to video chat with our engineer directly.

4 What g-code does the machine read?Can we integrate a post processor into our current software?

As this machine has auto labeling function ,so except standard .nc file,it also need XML and BMP pictures for label.You can ask sales engineers to send you detail format and explanation of files and show it to your software supplier. But this machine can definitely work with your software for sure.

5 Is there any other optional for this nesting cnc?

Except you can choose your own machine size , you can also choose any brand of machine parts, such as controller, servo ,spindle,vacuum pump, drilling head and so on.

6 We need a Declaration of Conformity,a CE certificate, does this machine have it?

Yes,there is CE certificate and Declaration of Conformity for this machine.

Quality control :

we extramely control all accuracy for each step of machine, for example linear rail installation,helical gear installation, spindle vertical accuracy testing,total accuracy of total machine,and we use ball bar testing and renishaw laser to control those accuracy of cnc machines:

EXIHIBITION:

Our company actively participates in various domestic trade shows and exhibitions annually, especially CIFF Guangzhou and CIFF shanghai. These events are vital platforms for us to showcase our latest woodworking products, connect with domestic customers, and stay abreast of market trends and technological advancements within China in woodworking trends.

In addition to our domestic engagements, we also extend our reach by participating in international trade fairs. This global approach allows us to expand our market presence and engage with a broader customer base. We have attended exhibitions in countries like USA,CANADA and Vietnam.... which are strategic markets for our business.

| Series | Smart 49 Pro | Smart 2130 Pro |

| Working size | 1220*2800*150mm | 2100*3000*150mm |

| Table size | 1220*2800mm | 2100*300mm |

| Transmission | X Y rack and pinion,Z ball screw | X Y rack and pinion,Z ball screw |

| Spindle | 9kw ISO30 | 9kw ISO30 |

| Travelling speed | 50m/min | 50m/min |

| Working speed | 20m/min | 20m/min |

| Driving system | Syntec servo / Weihong servo | Syntec servo / Weihong servo |

| Controller | Syntec controller/Weihong | Syntec controller/Weihong |

| Voltage | AC380V/220V,50/60HZ,3PH | AC380V/220V,50/60HZ,3PH |

| Dimension | 16000*6000*2300mm | 18000*7450*2300mm |

DESCRIPTION

1. Intelligent production solutions: Automatic nested cell is one of the intelligent solutions in the automatic production line of panel furniture. By integrating the labeling system, nested CNC router and a variety of auxiliary equipment, it minimizes manpower demand, improves material utilization, and supports large-scale and customized production.

2. Efficient automation process: The unit is composed of high-speed automatic labeling machine, two automatic loading and unloading ATC nested CNC machines, power drum line and central control system. The operator simply places the board on the lifting platform, the labeling machine will automatically label it, and the central control system then automatically assigns it to the nested center for cutting.

3. Optional robot system: The optional robot system can be used to complete pallet, surplus materials and waste output.

4. Central control system: with the function of optimizing the cutting program, saving time and reducing plate waste. At the same time, it supports the field supply of plates, and single plates can be processed without making documents and importing data. Up to approximately 230-260 panels in 8 hours.

5. Easy operation: Even ordinary workers can easily operate the nested units. The operator only needs to copy the processing program to the central control system and start the machine without operating each machine.

6. Optimized plate treatment: Optimize and rapidly promote the wood board treatment under the same order to improve efficiency and bring significant benefits.

7. Continuous multiple shift operation: nested units can run continuously in several shifts, reducing human restrictions and standby time.

8. Reduce production errors and material damage: effectively reduce production errors and material damage caused by human operation.

9. Production process monitoring: more convenient to monitor the whole production process.

10. Customization options: Customers can customize the size of the machine and many other configurations, including the size of the unit, the number and model of nested machines.

FREQUENT ASKED QUESTIONS:

1 Can i just buy one part of machine ,and later when big production needed, i will buy other other part?

Definitely yes, you can tell us your production area ,so let us make layout for you.All input and output port prepared well if you just buy part of them, and later can just buy and connect two nesting cnc machine together.

2 What is maximum cutting size of this machine? Or Can i customize maximum cutting size of nesting cnc machine?

The maximum cutting size of this nesting cnc router is 1220*2800mm,option is suitable for European panel size 2070*2800mm. And you can also customize machine size if you have bigger size needed.

3 Will there be instructions attached with machine,which i can follow to learn how to operate this cnc nesting machine?

There is one pen driver attached in machine tool box, in which there is instructions operation and maintenance,besides we have YouTube videos to show installation and operation of cnc router machine,except all of this ,you can choose to video chat with our engineer directly.

4 What g-code does the machine read?Can we integrate a post processor into our current software?

As this machine has auto labeling function ,so except standard .nc file,it also need XML and BMP pictures for label.You can ask sales engineers to send you detail format and explanation of files and show it to your software supplier. But this machine can definitely work with your software for sure.

5 Is there any other optional for this nesting cnc?

Except you can choose your own machine size , you can also choose any brand of machine parts, such as controller, servo ,spindle,vacuum pump, drilling head and so on.

6 We need a Declaration of Conformity,a CE certificate, does this machine have it?

Yes,there is CE certificate and Declaration of Conformity for this machine.

Quality control :

we extramely control all accuracy for each step of machine, for example linear rail installation,helical gear installation, spindle vertical accuracy testing,total accuracy of total machine,and we use ball bar testing and renishaw laser to control those accuracy of cnc machines:

EXIHIBITION:

Our company actively participates in various domestic trade shows and exhibitions annually, especially CIFF Guangzhou and CIFF shanghai. These events are vital platforms for us to showcase our latest woodworking products, connect with domestic customers, and stay abreast of market trends and technological advancements within China in woodworking trends.

In addition to our domestic engagements, we also extend our reach by participating in international trade fairs. This global approach allows us to expand our market presence and engage with a broader customer base. We have attended exhibitions in countries like USA,CANADA and Vietnam.... which are strategic markets for our business.

| Series | Smart 49 Pro | Smart 2130 Pro |

| Working size | 1220*2800*150mm | 2100*3000*150mm |

| Table size | 1220*2800mm | 2100*300mm |

| Transmission | X Y rack and pinion,Z ball screw | X Y rack and pinion,Z ball screw |

| Spindle | 9kw ISO30 | 9kw ISO30 |

| Travelling speed | 50m/min | 50m/min |

| Working speed | 20m/min | 20m/min |

| Driving system | Syntec servo / Weihong servo | Syntec servo / Weihong servo |

| Controller | Syntec controller/Weihong | Syntec controller/Weihong |

| Voltage | AC380V/220V,50/60HZ,3PH | AC380V/220V,50/60HZ,3PH |

| Dimension | 16000*6000*2300mm | 18000*7450*2300mm |

Copyright 2022 DWD MECHATRONICS CO.,LTD

Sitemap |Technology by leadong.com