close

Choose Your Site

Global

Social Media

SmartNest LabelDrill CNC

What this production line can do ?

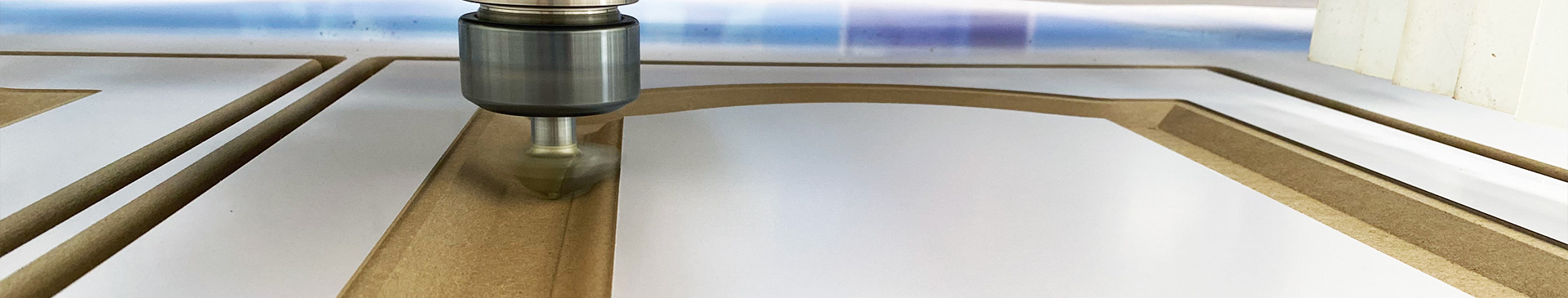

The SmartNest LabelDrill CNC comprises three main components: auto labeling, auto drilling, and auto nesting. Initially, an operator loads panels onto the scissor lift table. Subsequently, when the file is initiated, the label machine positions the panel and applies labels. Once labeled, the machine transfers the panels to the auto drilling machine. Here, two grippers secure the panel in place for the top and bottom drills to create various holes on both the top and bottom sides. Additionally, the top and bottom spindles create slots on both sides of the panel. Following the drilling process, the panel is conveyed to the auto nesting machine for cutting.

What this production line used for ?

This machine is specifically tailored for the production of panel furniture, including cabinets, kitchens, wardrobes, and cupboards. Typically, these types of furniture utilize cam lock and minifix connectors. Our total production line is intricately designed to cater to these specific connectors, ensuring seamless and efficient manufacturing processes.

What is efficiency of this production line?

| Material | Thickness(mm) | Cutting speed m/min | Cutting efficiency (8 hour per day) |

| Polywood | 15-25 | 12-25 | 130 sheets (1220*2800mm) |

| HMR MDF | 15-25 | 12-25 | 130 sheets (1220*2800mm) |

| Particleboard | 15-25 | 12-25 | 130 sheets (1220*2800mm) |

| Chipboard | 15-25 | 12-25 | 130 sheets (1220*2800mm) |

| Ecology board | 15-25 | 12-25 | 130 sheets (1220*2800mm) |

| OSB | 15-25 | 12-25 | 130 sheets (1220*2800mm) |

SmartNest LabelDrill CNC

What this production line can do ?

The SmartNest LabelDrill CNC comprises three main components: auto labeling, auto drilling, and auto nesting. Initially, an operator loads panels onto the scissor lift table. Subsequently, when the file is initiated, the label machine positions the panel and applies labels. Once labeled, the machine transfers the panels to the auto drilling machine. Here, two grippers secure the panel in place for the top and bottom drills to create various holes on both the top and bottom sides. Additionally, the top and bottom spindles create slots on both sides of the panel. Following the drilling process, the panel is conveyed to the auto nesting machine for cutting.

What this production line used for ?

This machine is specifically tailored for the production of panel furniture, including cabinets, kitchens, wardrobes, and cupboards. Typically, these types of furniture utilize cam lock and minifix connectors. Our total production line is intricately designed to cater to these specific connectors, ensuring seamless and efficient manufacturing processes.

What is efficiency of this production line?

| Material | Thickness(mm) | Cutting speed m/min | Cutting efficiency (8 hour per day) |

| Polywood | 15-25 | 12-25 | 130 sheets (1220*2800mm) |

| HMR MDF | 15-25 | 12-25 | 130 sheets (1220*2800mm) |

| Particleboard | 15-25 | 12-25 | 130 sheets (1220*2800mm) |

| Chipboard | 15-25 | 12-25 | 130 sheets (1220*2800mm) |

| Ecology board | 15-25 | 12-25 | 130 sheets (1220*2800mm) |

| OSB | 15-25 | 12-25 | 130 sheets (1220*2800mm) |

Copyright 2022 DWD MECHATRONICS CO.,LTD

Sitemap |Technology by leadong.com