close

Choose Your Site

Global

Social Media

Views: 57 Author: Site Editor Publish Time: 2022-07-11 Origin: Site

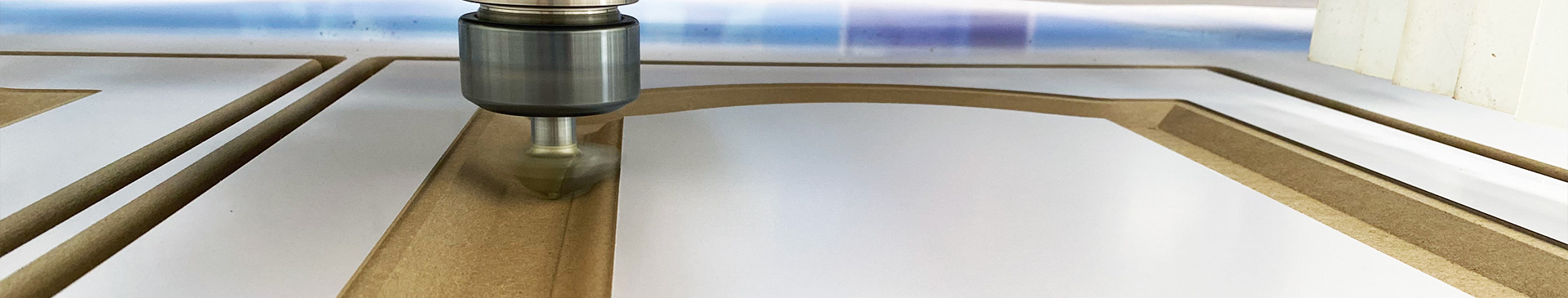

Today, CNC nesting router are widely used in manufacturing sites. How did nested machining centers come into being and develop? What are the types and functions of nested machining centers?

l What are the main functions of nesting machining centers?

l What is the evolution of nesting centers?

l What are the requirements of CNC machining process?

1. In addition to the main purpose of mold manufacturing, machining centers are key equipment for processing metal parts and assemblies. For example, machining centers in the automobile industry are used for engine parts

2. Efficient grinding and drilling, as well as molds used to manufacture body parts. Many other products commonly used in everyday life and industrial Settings are manufactured in processing centers.

3. Machining center with computer automatic tool change function. In general, the operator must change the tool on a CNC machine. However, the machining center has a replacement arm that automatically retrieves and replaces tools from the tool bank during workpiece processing. This saves the time and effort required for standard tool replacements, resulting in automated and energy-efficient operations while reducing costs.

1. Manufacturing metal parts usually involves grinding surfaces and grooves, in addition to many complex machining methods, such as drilling, drilling (enlarging holes), and threading. Traditionally, different cutting tools, such as milling cutters, endmills, drills, boring cutters, and taps, have been used selectively for these processes.

2. Later, with the emergence of CNC lathes, the development of a tool tower called the manual tool change function, so that the tool changes more convenient. The machining center takes this idea a step further with computer-controlled automated tool exchanges. The machining center can simultaneously and continuously process various types of workpieces on different surfaces, which greatly improves the production efficiency. Even today, with yearly improvements in machining accuracy and speed, machining centers continue to improve, making them an essential part of the manufacturing process.

1. In CNC programming, the size and position of all points, lines and surfaces are based on the programming origin. Therefore, it is best to give the coordinate dimensions directly on the part drawing, or try to refer to the same reference dimensions.

2. In programming, programmers must fully master the parameters of geometric elements that constitute the contour of parts and the relations between them. Since all geometric elements of the part contour are defined in the automatic programming process, the coordinates of each node must be calculated in the manual programming process. No matter what is ambiguous or uncertain, it cannot be programmed. However, due to the lack of consideration or neglect in the design process, part designers often have incomplete or unclear parameters, such as arc and straight line, arc and arc whether tangent or intersection or separation. Therefore, in the review of drawings, analysis of drawings, we must be careful, find problems and timely contact the designer.

3. In NUMERICAL control machining, processing steps are often more centralized, with the same benchmark positioning is very important. As a result, it is often necessary to set some secondary benchmarks or add some process bosses in the margins.

4. It is best to use a uniform geometric type or size for the shape and cavity of the parts. This can reduce the number of knife changes. Control programs or special programs can also be used to shorten the program length. The shape of the parts is symmetrical as far as possible, which is convenient for programming with the mirror processing function of CNC machine tools and saves programming time.

Choosing the right CNC nesting router can certainly improve productivity, save labor, and bring more profit. If you are looking for a CNC nesting machine device with good price and quality, DWD MECHATRONICS CO., LTD is a good choice.

Copyright 2022 DWD MECHATRONICS CO.,LTD

Sitemap |Technology by leadong.com