close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2022-06-06 Origin: Site

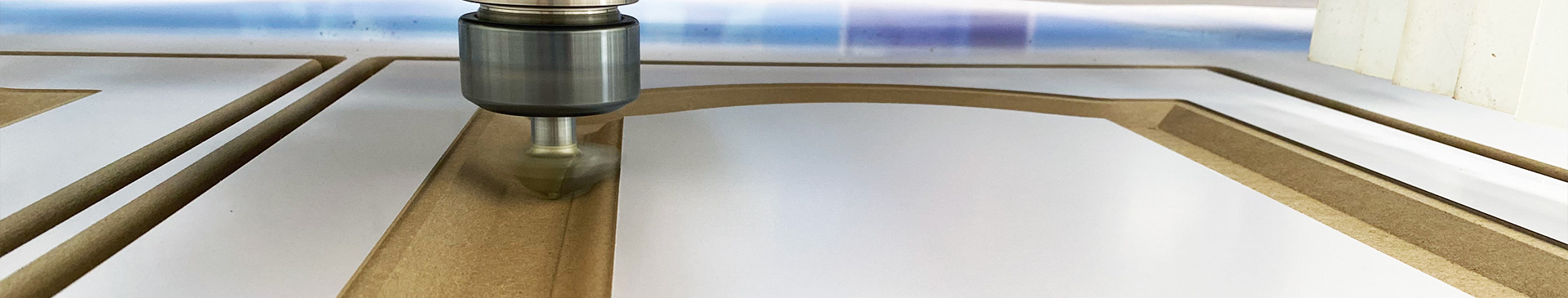

CNC nesting router is widely used in the production line of panel furniture. More and more people choose CNC cutting machine. What makes CNC machines stand out?

l What are the advantages of the CNC wood Nesting machine?

l How to maintain CNC wood Nesting machine?

l What are the advantages of the CNC wood Nesting machine?

1. Compared with traditional machines, the configuration of CNC cutting machine has been improved, and its control system has been upgraded and improved. The data processing speed is fast, so the cutting speed is fast, the operation is stable, the cutting precision is high.

2. CNC machines with automatic tool change system. If the aperture is large, the processing of large diameter three holes, rubber particle holes and wood pin holes can be realized through reaming holes to meet the production process requirements.

3. The CNC wood Nesting machine has professional nesting software that can use intelligent nesting, zero error, improve the utilization rate of sheet metal and reduce sheet metal waste.

4. Woodworking cutting machine high degree of automation, one person can operate it. Professional cutting software is easy and fast to use, and can be adjusted according to customer requirements without professional designers.

1. To do a good job of mesa and woodworking cutting machine parts of the dust removal work. Once the dust enters the equipment, it will cause great trouble to the equipment, affect the normal use of the equipment and affect the production efficiency. Therefore, in daily use, it is necessary to do a good job of cleaning the surface of the machine and the casing.

2. The woodworking cutting machine must be plugged in with the power supply corresponding to the rated voltage, otherwise it will cause damage to the woodworking cutting machine.

3. Woodworking cutting machine is mainly composed of a variety of metal parts, so woodworking cutting machine cannot be placed in a wet environment for a long time, otherwise it will cause strong corrosion of woodworking cutting machine, reduce its service life.

1. Lubrication of feeder transmission device. When the equipment is running, if the transmission device of the equipment is not running smoothly, it will cause uneven feeding of the equipment, affecting the quality of blanking and industrial production. Therefore, it is very important to lubricate the transmission device of the equipment in daily maintenance.

2. When using the woodworking cutting machine, do not replace or destroy the original parts and cables of the woodworking cutting machine. Original accessories according to the corresponding requirements of woodworking cutting machine configuration. If replaced, damage or accidents may occur. Although the daily maintenance of woodworking cutting machine is trivial, one of the tasks to ensure the performance of equipment is of great significance for prolonging the service life of woodworking cutting machine.

CNC wood Nesting machine Simple operation, high plate utilization, high production efficiency, labor saving, cost reduction and other advantages are what most furniture manufacturers need. If you are looking for a CNC nesting router with good price and quality, DWD MECHATRONICS CO.,LTD is a good choice.

Copyright 2022 DWD MECHATRONICS CO.,LTD

Sitemap |Technology by leadong.com