close

Choose Your Site

Global

Social Media

Views: 48 Author: Site Editor Publish Time: 2022-07-14 Origin: Site

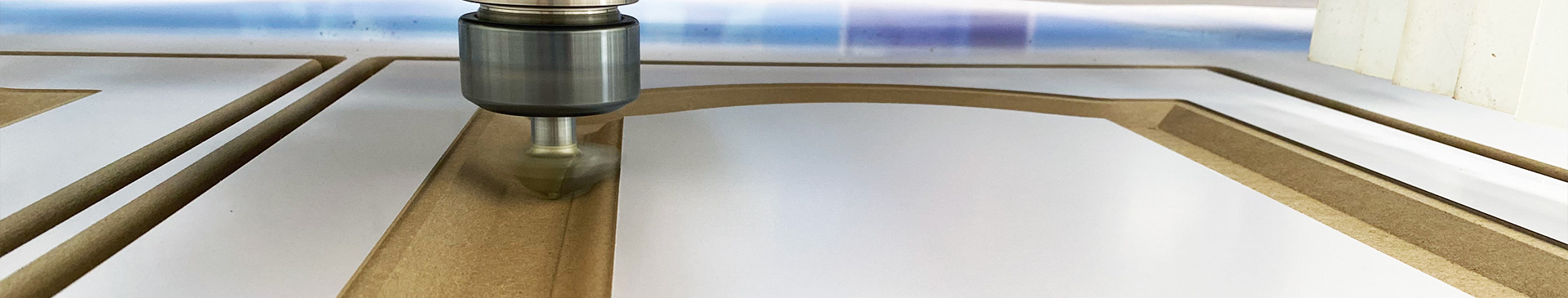

Why can CNC nesting machine be widely used by many industries? How does a CNC machine work? What are the features and advantages of the CNC nesting router?

l What is a CNC nesting machine?

l What is a CNC machine tool?

l What are the features and advantages of the CNC nesting machine?

CNC machines make parts for almost every industry around the world. They make things out of plastic, metal, aluminum, wood, and many other hard materials. The word "CNC" stands for computer numerical control, but today everyone just calls it CNC. So, how to define CNC machine tools? All automatic motion control machines have three main components -- command function, drive/motion system and feedback system. CNC machining is the process of producing parts from solid materials of different shapes using computer-driven machine tools.

CNC relies on digital instructions typically produced on computer-aided manufacturing (CAM) or computer-aided design (CAD) software such as SolidWorks or MasterCAM. The software writes G code that can be read by the controller on the NC machine. A computer program on the controller interprets the design and moves the cutting tool and/or workpiece on multiple axes to cut the desired shape from the workpiece. The automatic cutting process is faster and more accurate than manually moving tools and workpieces with levers and gears on older equipment. Modern CNC machines have many tools and perform many types of cutting. The number of planes of motion (axes) and the number and type of tools that the machine can access automatically during processing determine the complexity of the workpiece that a CNC can produce.

1. CNC machining process is suitable for a wide variety of parts manufacturing, new CNC machining parts can be produced with new procedures, without replacing the machine and controller.

2. CNC machine tools are processed according to CAM instructions, eliminating errors caused by manual intervention. Multiple measurements will be made to ensure high precision and rigidity and dimensional accuracy of the parts. The machining accuracy of CNC machine tools has been improved from ±0.01mm to ±0.005mm or even higher. In addition, through compensation technology, CNC equipment can achieve higher processing accuracy than their own, improve the production consistency of the same batch of precision CNC processing parts, to ensure a higher pass rate and stable processing quality.

3. CNC machine tool spindle speed and feed range is larger than traditional machine tools, so each CNC process can choose the best cutting amount. More importantly, the rigid structure of the CNC machine enables it to perform strong cutting with large cutting volumes, thus improving the cutting efficiency. When machined parts change, there is little need to readjust and re-check the machine. One machine can realize continuous processing of multiple processes. Faster moving speed, automatic knife change, shorten the clamping time, greatly shorten the production time.

4. Traditional manufacturing equipment is difficult to achieve more than 3 times of curve or surface movement, such as propeller, turbine blade spatial surface, while CNC machine can move along any direction. Track and processing arbitrary shape of the surface, can process complex and irregular parts.

5. While CNC machines and tools are not cheap or even expensive, CNC machining technology can directly reduce costs by saving time on marking, adjusting, machining and inspection. The stable quality and precision of CNC machining services also reduce the rejection rate, further saving costs.

A CNC nesting machine can realize a variety of uses such as machining center, save plant area and building investment, and bring economic benefits. If you are looking for a CNC nesting router device with good price and quality, DWD MECHATRONICS CO.,LTD is a good choice.

Copyright 2022 DWD MECHATRONICS CO.,LTD

Sitemap |Technology by leadong.com