close

Choose Your Site

Global

Social Media

Views: 60 Author: Site Editor Publish Time: 2022-07-07 Origin: Site

What is the main use of the CNC wood Nesting machine? What industry will need to use CNC nesting router? CNC woodworking nesting machine has what parts?

l What is the CNC wood Nesting machine?

l Where can CNC wood Nesting machine be used?

l What are the components of the CNC wood Nesting machine?

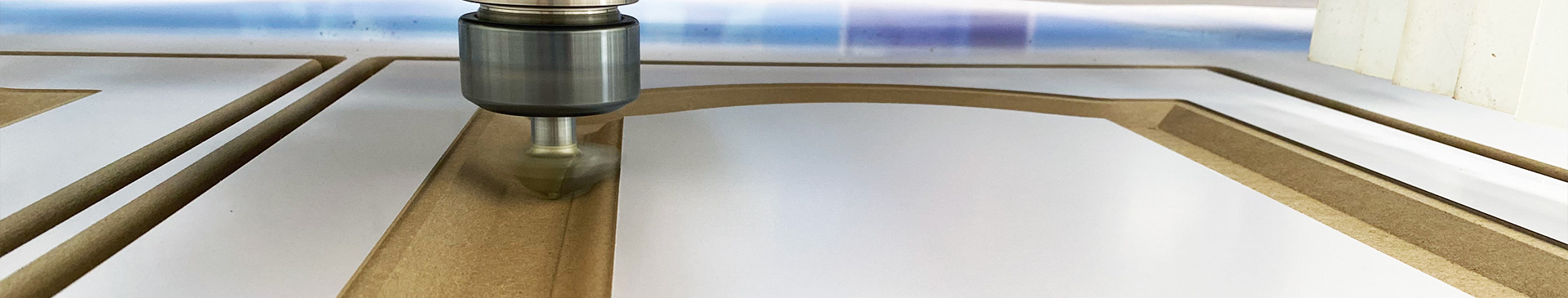

The CNC wood Nesting machine is a CNC machine shaped specifically for the manufacture of panel furniture. Its main function is to cut wooden boards. When processing, cutting machine includes cutting, punching, slotting and other processes. Generally, through the blueprint of intelligent software, nesting CNC machine tool automatically improve typesetting design, generate effect drawings, spontaneous modification and other operations, cannot help but generate a variety of paths. As a result, it saves and improves paper utilization. Fortunately, CNC nesting machine is often used in cabinets, wardrobe, solid wood, paint free, solid wood composite, door and other furniture industry.

1. Furniture industry: panel furniture, cabinets, sliding doors, soft bags, office furniture, wooden doors, whole house customization, etc.

2. Wood products: sound box, game cabinet, computer table, sewing machine table, Musical Instruments;

3. Sheet metal processing: insulation parts, plastic chemical parts; Circuit board; Motor vehicle interior, bowling alley; Anti-folding special plate, epoxy resin, ABS, PP, PE and other carbonized mixture;

4. Decoration industry: acrylic, PVC, density board, plexiglass, plastic, copper and aluminum soft metal plate carving cutting.

1. Many manufacturers and customers often ignore the importance of bed frame structure, because the nesting CNC milling machine and ordinary woodworking engraving machine frame and not engaged in production and processing. But in fact, the bed is the foundation of the whole device, which contains many overlooked details. Nesting CNC engraving mechanical and electrical machine running, the speed is very fast. In order to ensure that the processing process does not shake, need a bed frame with stability and timeliness. This requires manufacturers to have a very strong processing capacity and professional processing personnel (excellent manufacturers will generally be equipped with special five face milling equipment for this kind of processing). If the bed is not heavy enough, it will not produce jitter, which will directly affect the accuracy of processing. Therefore, it will affect the quality of the product.

2. Rack selection of CNC nesting machine represents different degrees of accuracy and stability. If the engagement degree of the rack of poor quality is not accurate enough, wear resistance is not enough, not only the movement of the gantry is unstable, but also produces a lot of noise. The use of a good rack, not only can improve the accuracy and stability of the equipment processing process, but also can increase the service life of the product. details

3. The X, Y and Z axes of CNC nesting machine are equipped with a guide rail, and the guide rail is also the most important part of CNC nesting machine accessories. A high-quality guide rail can not only make the processing process faster, smoother, more accurate. And it's easy to maintain. With the increase of the number of uses, the quality of the poor will not only slide phenomenon, and after maintenance will appear the original group of accessories cannot engage the phenomenon. details

4. Cables not to be ignored. The cable used for such a large device is not a phone charging cable, but just to keep the current flowing. In long-term machining, the cable is bent tens of thousands of times, and its interior changes millions of times per second. Signal strength interspersed, but also to consider the impact of the weather on the strength of artillery shells. Even if a small part of the cable is damaged, the whole equipment cannot work properly. Therefore, the equipment must be returned to the factory for replacement. Therefore, good cable must have strong wear resistance, high temperature resistance, acid and alkali resistance, high flexibility.

Imagine what a CNC wood Nesting machine could do for various industries. If you are looking for a CNC nesting router device with good price and quality, DWD MECHATRONICS CO.,LTD is a good choice.

Copyright 2022 DWD MECHATRONICS CO.,LTD

Sitemap |Technology by leadong.com